Chemical Ingredient Corp. owns a number of chemical laboratories dedicated to developing and trailing new material compositions. They create samples in their research and development facilities through the mixture of all raw materials depending on distinct processes that provide scientists with series of procedures in developing the ingredients. The client’s operations involve steady innovation and the development of new products through complex and time-consuming procedures.

The client wanted to reduce the amount of time and energy needed to verify the ready application every time a new one is created or an existing one is altered. Secondly, they should automate repetitive workflows, such as creating experimental or new materials, to increase efficiency. Thirdly they wanted to decrease the number of repetitive operations to which scientists are exposed and free up their time for experimentation and research.

Every time client’s application was changed, the workflows also had to be checked manually, which cause many problems and a lot of work.

Another challenge was that the client’s scientists were working a lot on administrative work - testing the application and developing new materials, rather than on invention.

These two phases, testing and material creation were not integrated well for scaling thus the client was struggling to improve throughput without escalating manual work.

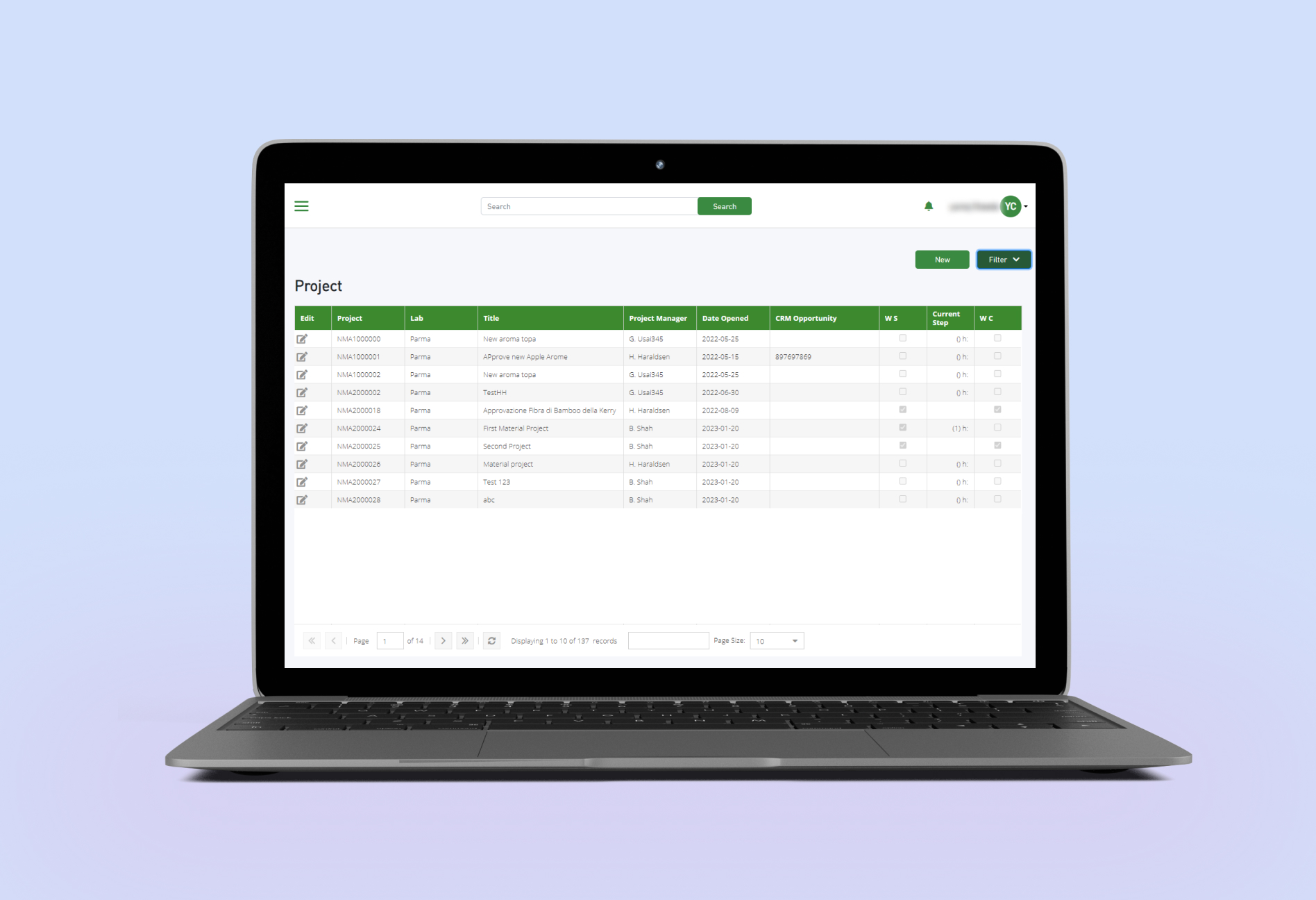

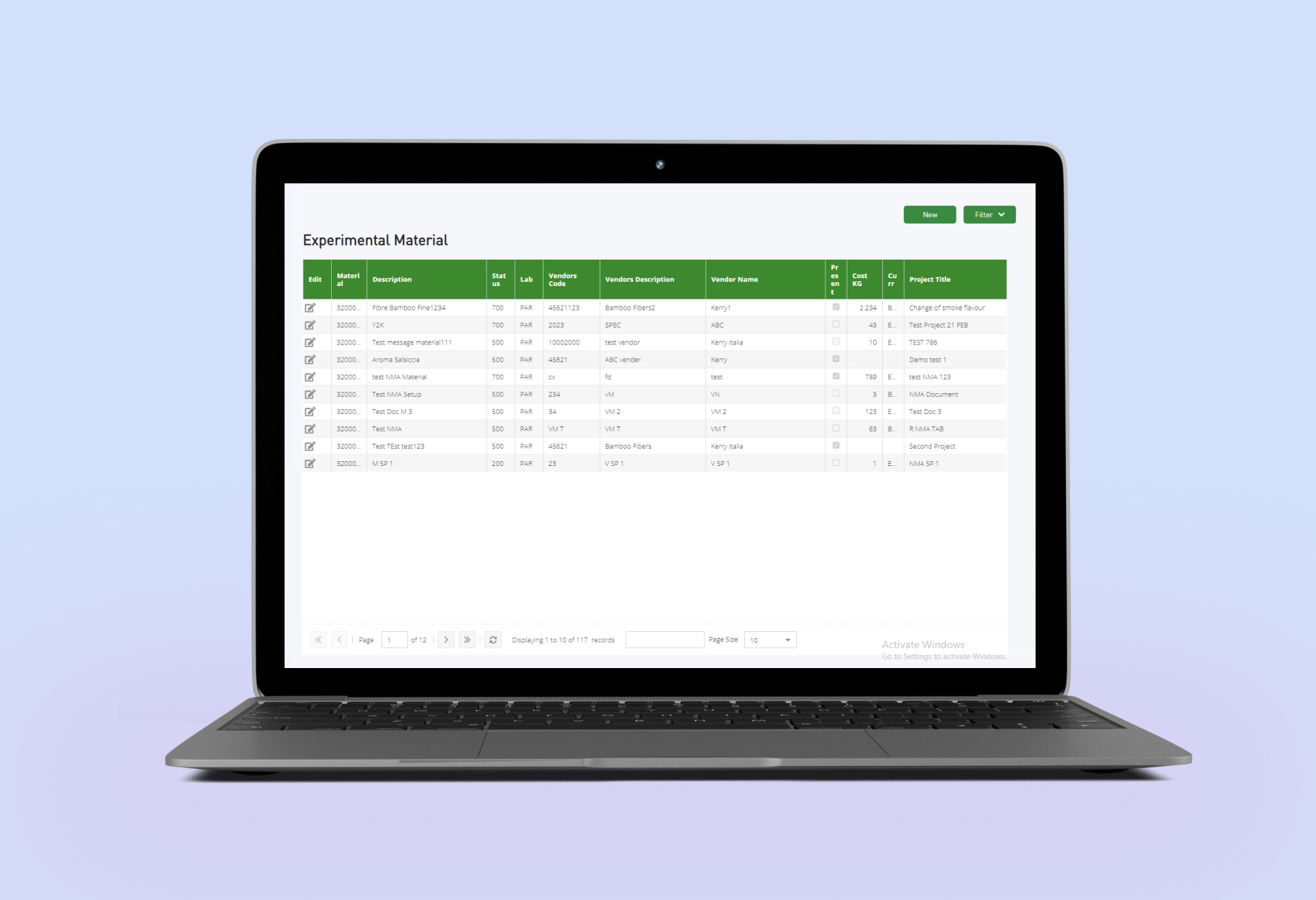

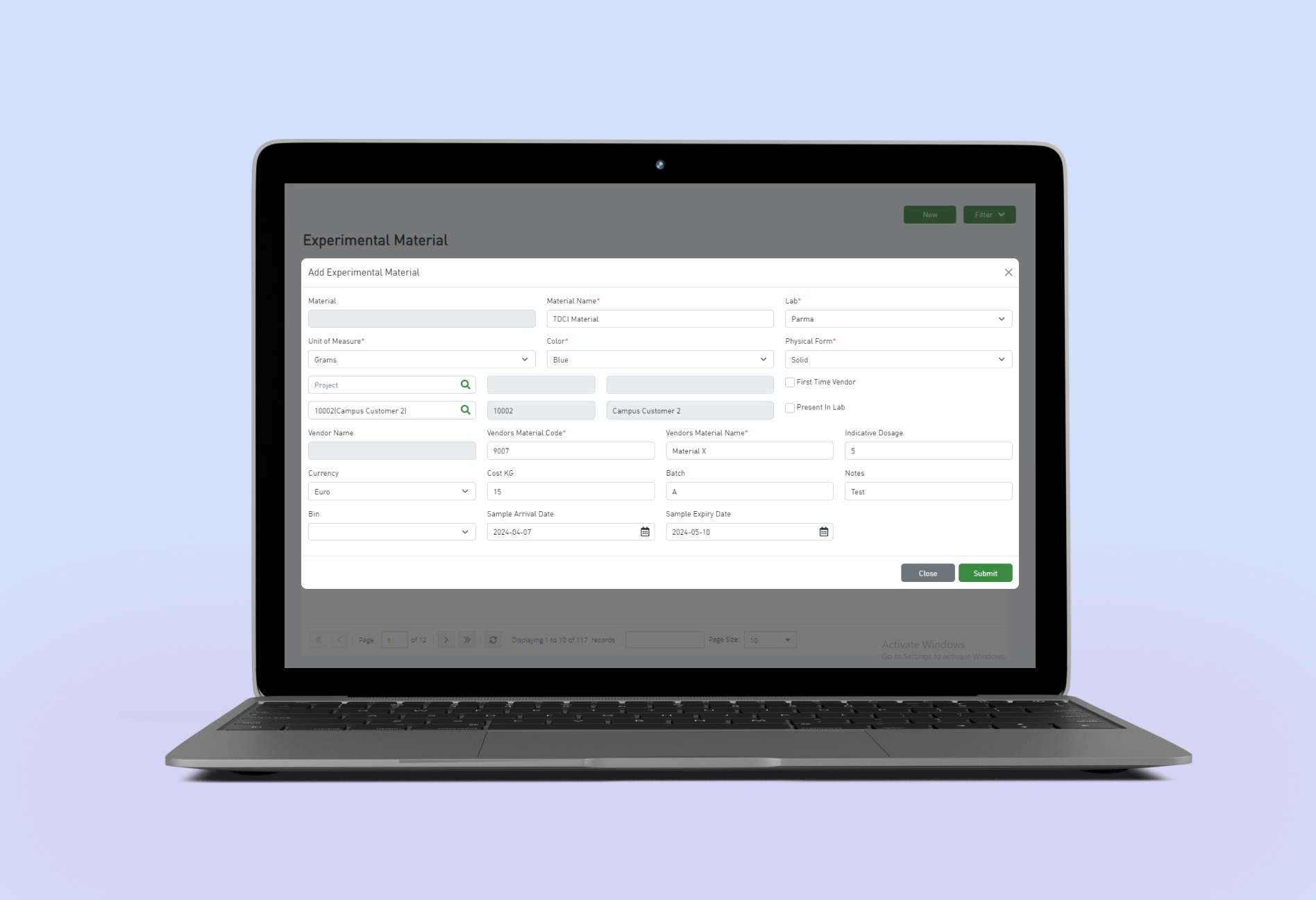

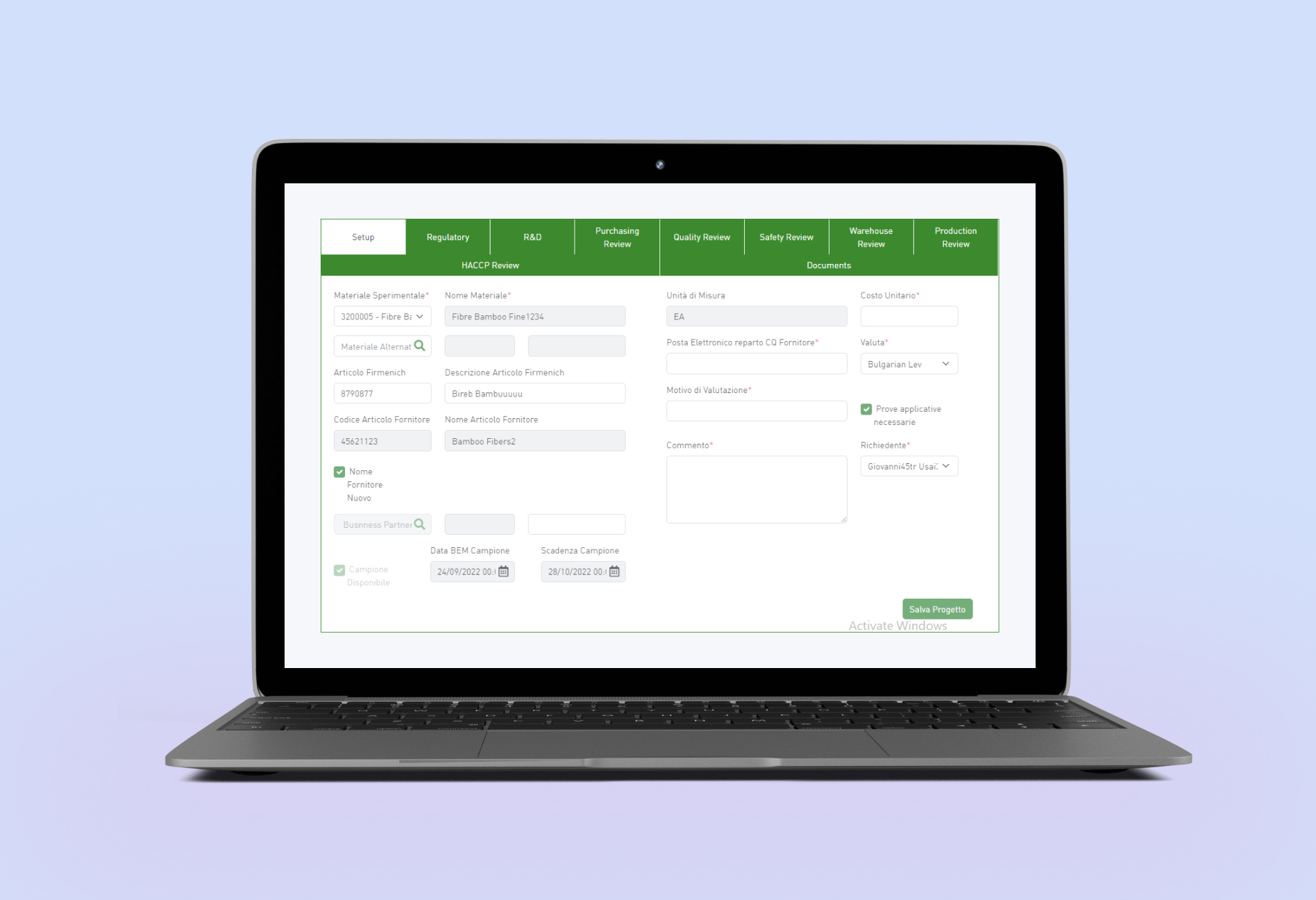

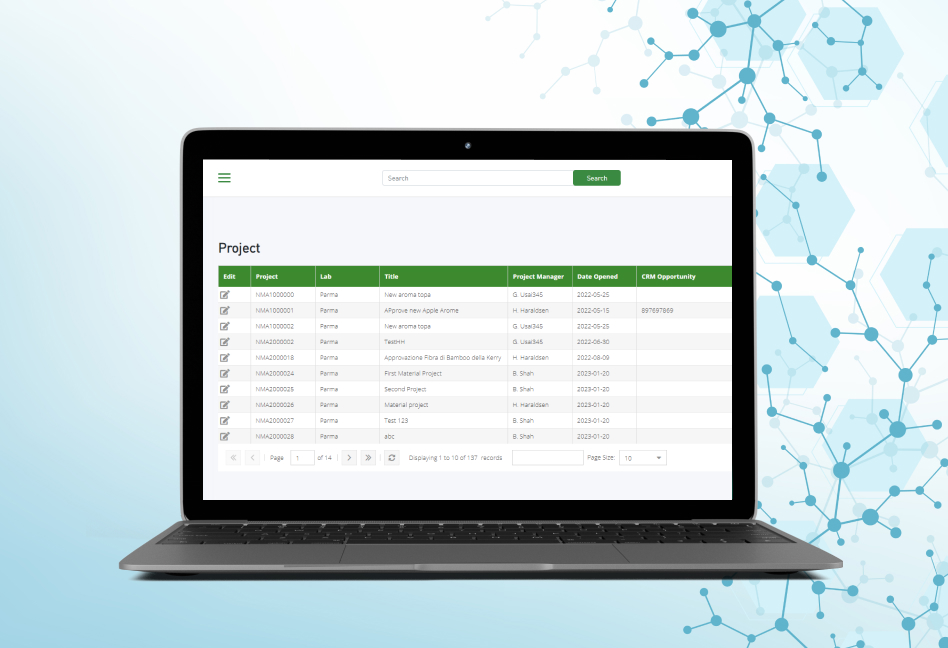

Exploring the client’s daily activity, we identified the processes that are performed most frequently and time-consuming, focusing on the processes connected with the materials’ creation. These were fully automated in order to minimize interaction In human operators.

Scientists no longer needed to perform repetitive tasks. By inputting relevant data into an Excel sheet, the automation script could take over and complete the workflow, saving time and effort.

As already mentioned above, this software is highly suitable for multi-browser testing. We made sure that the solution was developed to be compatible with multiple browsers to operate harmoniously in an environment of the client’s choice.

We closely collaborated with the client to understand the specific workflows that needed automation.

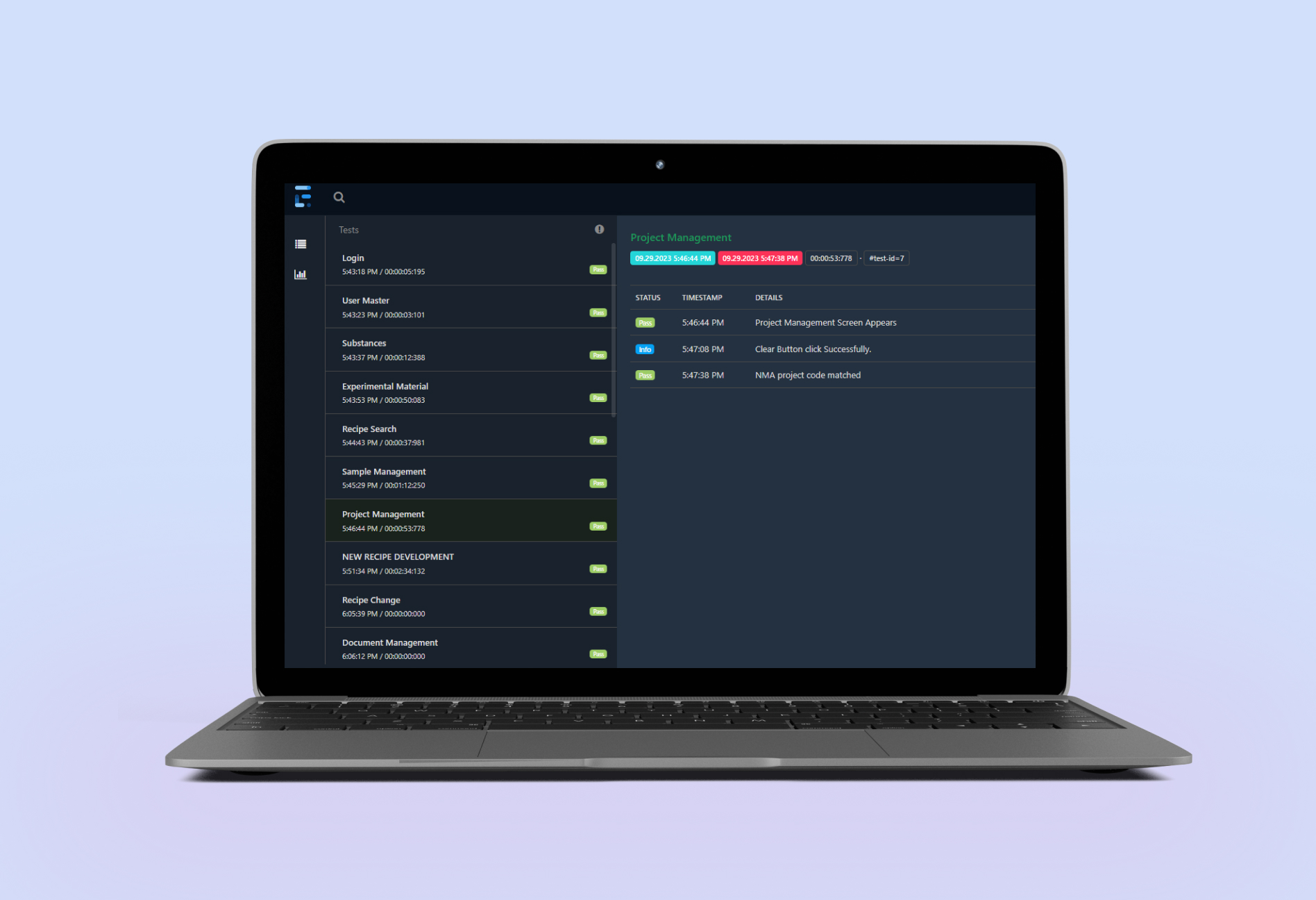

Using Selenium TestNG with Java, we created an automation script that could handle repetitive processes.

The automation was designed to require minimal input from the user—scientists only needed to provide data through an Excel sheet.

The automation script was tested across different browsers to ensure full compatibility.

Detailed test reports were generated after each execution, and the system was continuously refined based on feedback.

The current automation solution immensely cut on the amount of time taken for testing and repetitive tasks hence giving the scientists more time to think through.

Apart from this the automation worked to lessen the number of manual interfaces in the material production workflows.

Instant conveyor of operations minimized the chances of developing errors in the course of testing as compared to manual handling.

SPEC House, Parth Complex, Near Swastik Cross Roads, Navarangpura, Ahmedabad 380009, INDIA.

This website uses cookies to ensure you get the best experience on our website. Read Spec India’s Privacy Policy